Medical electrodes play a vital role in contemporary healthcare, allowing for the measurement and recording of electrical signals emitted by the human body. These signals offer insights into various physiological processes and are essential for diagnosing and monitoring medical conditions. Operating by converting the body’s ionic current energy into electrical current, medical electrodes are used to detect and evaluate a range of disorders, including muscular, ocular, nervous, and cardiac diseases.

The manufacturing process behind medical electrodes takes advantage of state-of-the-art micro/nanofabrication technologies. Techniques such as magnetron sputtering and electrochemical deposition enable the production of these life-saving devices at a relatively low cost and on a scalable level. This has streamlined their availability and utility for medical professionals, who increasingly rely on medical electrodes for accurate and non-invasive diagnostics.

As medical electrodes have become indispensable tools in modern medicine, understanding their applications and manufacturing processes is crucial for healthcare professionals and researchers alike. This article delves into the intricate world of medical electrodes, shedding light on their diverse uses, design innovations, and the technologies behind their production.

Basics of Medical Electrodes

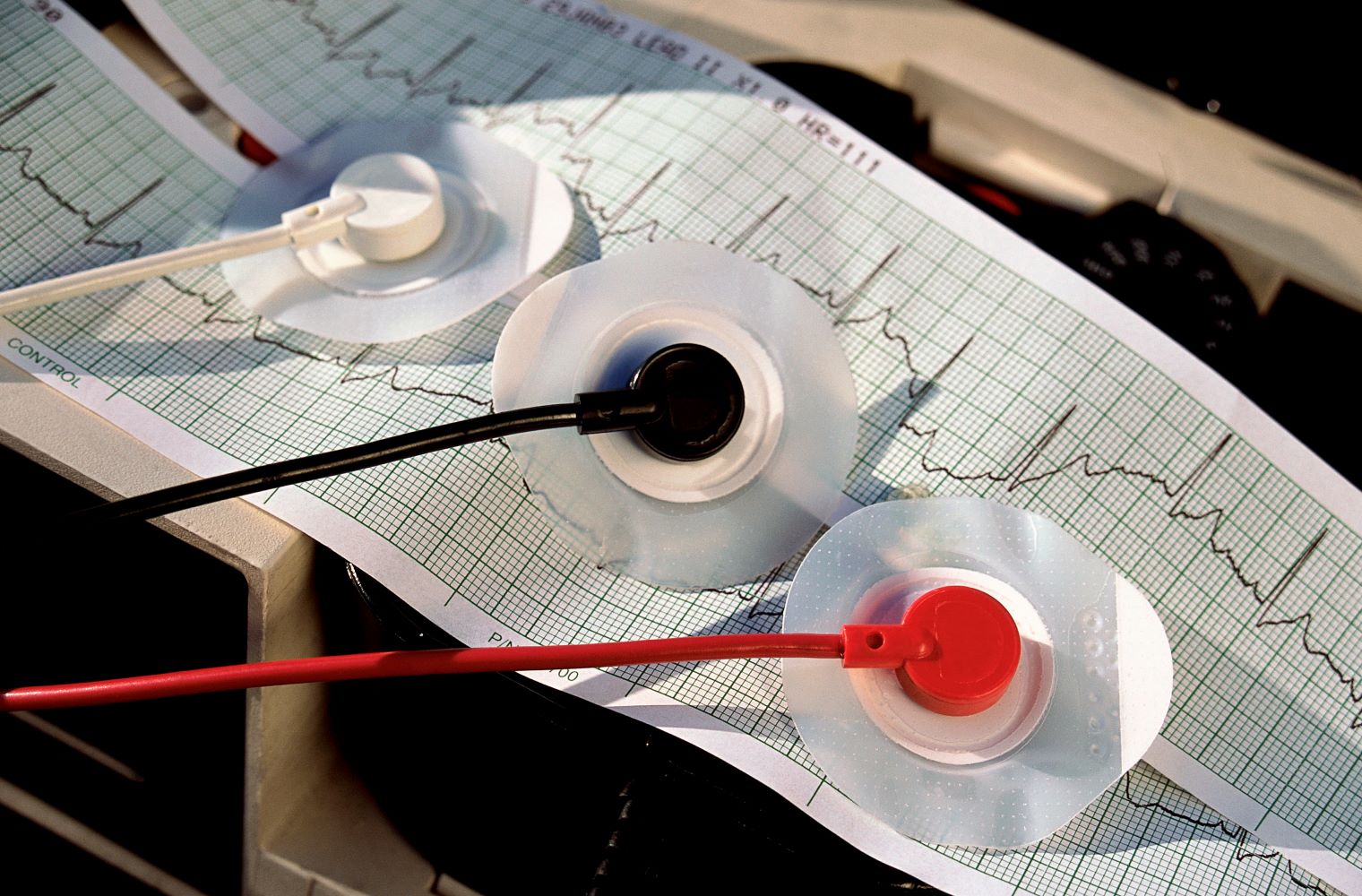

Medical electrodes are essential tools used in various medical procedures to diagnose and monitor numerous diseases by converting the body’s ionic current energy into electrical current signals. They are typically composed of a lead for electrical current conduction, a metal electrode, and an electrode-conducting paste or gel for surface electrodes. A metal snap is often present to provide good electrical contact, allowing the electrode to be disposable while the lead can be reused.

One commonly used type of medical electrodes is surface electrodes. These electrodes make direct contact with the skin and are employed in non-invasive measurements. Procedures such as electrocardiography (ECG) and electromyography (EMG) utilize surface electrodes to capture electrical signals generated by the underlying tissues.

In the manufacturing process of medical electrodes, factors like material selection, production techniques, and quality control measures are crucial aspects to ensure their functionality and safety. The construction of the electrode starts with the choice of a suitable metal, typically silver or silver chloride, to conduct electrical signals effectively. The metal electrode is then affixed to an adhesive pad or coating designed for skin contact. This adhesive pad may contain a conductive gel or paste that enhances signal transmission.

Quality control measures in the manufacturing process are vital to ensure the high performance and reliability of medical electrodes. These measures may include rigorous testing of the raw materials, regular monitoring of production equipment, and strict adherence to manufacturing guidelines and safety standards.

Types of Medical Electrodes

Medical electrodes are essential tools in modern healthcare, as they play a crucial role in monitoring and recording electrical signals from the body. These electrodes are carefully manufactured to ensure accurate and reliable measurements in various medical procedures and check-ups. Here, we will discuss the common types of medical electrodes used in the healthcare setting.

Surface Electrodes are widely used for non-invasive measurements and make direct contact with the skin. These electrodes are typically employed in procedures like electrocardiography (ECG) and electromyography (EMG), capturing electrical signals produced by the underlying tissues. Surface electrodes come in different forms, such as:

- Suction Electrodes offer good attachment to flat surfaces of the body and to regions with soft underlying tissue due to their contact surface. They have a small surface area, providing effective electrical contact without causing discomfort to the patient.

Needle Electrodes are employed for specialized purposes, such as electromyography, where they must be capable of piercing the skin. These electrodes are designed to retrieve electrical signals from deeper tissue layers and muscles, with minimal discomfort to the patient.

Microelectrodes come in two main variants:

- Metal Microelectrodes consist of a small metal wire that can make contact with cells or tissue, enabling researchers or clinicians to record electrical activity at a microscopic level.

- Micropipette Microelectrodes contain an electrolyte solution and are typically made from glass or other insulating materials. They can be used to study single cells and their electrical properties.

Different electrode materials, shapes, and designs provide various benefits and drawbacks, depending on their intended application. It is important for healthcare professionals to select the right type of medical electrode to ensure the most accurate and reliable measurements. The manufacturing process for these electrodes involves careful consideration of the electrode material, electrolyte interface, and skin contact impedance to maximize their effectiveness and minimize any potential for interference or inaccurate readings.

Functionality of Medical Electrodes

Medical electrodes play a crucial role in diagnosing and monitoring various health conditions by converting the body’s ionic current energy into an electrical current. These electrodes are mainly used in muscular, ocular, nervous, and cardiac disease diagnosis. Through their ability to detect biopotentials, they facilitate essential communication between biological systems and medical devices.

The core components of a medical electrode include a lead (for electrical current conduction), a metal electrode, and an electrode-conducting paste or gel for surface electrodes. Often, there is a metal snap for good electrical contact, allowing the electrode to be disposable while the lead can be reused.

Electrodes used in the biomedical field are designed to adhere to the skin surface and efficiently collect vital signs. Recent advances in electrode development have led to the creation of novel materials and structures that show improved sensing performance compared to conventional electrodes.

One common type of medical electrode is the fetal scalp electrode, which monitors a baby’s heartbeat within the uterus. These electrodes are not directly inserted into the baby’s skin, but rather penetrate the outer layers. Other examples of medical electrodes include EKG and EEG electrodes, which measure electrical activity in the heart and brain, respectively.

Medical electrodes need to be manufactured with high precision to ensure effectiveness and safety. Materials like silver, silver chloride, gold, and platinum are commonly utilized due to their excellent conductivity and biocompatibility. In addition, some modern electrodes are made from flexible materials, such as conductive polymers and textiles, to enhance patient comfort.

In conclusion, the functionality of medical electrodes relies on their ability to convert ionic current energy into electrical current for accurate diagnosis and monitoring of various health conditions. The precise manufacturing process enables electrodes to adhere to the skin surface and collect vital signs effectively, making them an essential tool in the medical field.

Manufacturing Process of Medical Electrodes

Materials Used

The manufacturing of medical electrodes begins with selecting appropriate materials. Common materials used for their biocompatible and conductive properties include:

- Metals: Silver, gold, platinum, and stainless steel are often used for their high conductivity and biocompatibility.

- Polymers: Medical-grade silicone is frequently utilized as substrates or coatings due to its flexibility and biocompatible nature.

- Conductive adhesives: These materials are applied to secure the electrodes to the skin or other surfaces, improving the quality of the electrical signal while maintaining comfort for the patient.

Molding and Shaping

Once the materials are chosen, they must be formed into the desired shape of the electrode. Methods for molding and shaping differ depending on the materials used and the application of the electrode:

- Metal electrodes: These are manufactured using processes such as electrodeposition, sputtering, or etching. The metal is shaped into thin films or wires, which are then cut into the required dimensions.

- Polymer-based electrodes: For flexible and comfortable electrodes, polymers like silicone can be molded using techniques like injection molding or extrusion. The desired shape is achieved by setting the polymer mixture into pre-made molds or by cutting it after the extrusion process.

Conduction Application

Once the base structure of the electrode is created, the conductive layer or material must be applied. This can be achieved through different methods, such as:

- Coating: Thin films of conductive materials can be applied to the surface of the electrode using techniques like physical vapor deposition (PVD) or chemical vapor deposition (CVD).

- Incorporating conductive materials: In polymer-based electrodes, conductive materials like carbon nanotubes or metallic particles can be mixed with the polymer, creating a conductive composite material.

- Connections: Electrodes need to have a reliable means of connecting to the monitoring or stimulation device. This might involve soldering wires, attaching conductive adhesive electrodes, or using snap-fit connectors.

Quality Control

Throughout the manufacturing process by an industrial converting company, strict quality control measures are essential to ensure the performance, safety, and biocompatibility of the medical electrodes. Key aspects of quality control include:

- Inspections: Visual and automated inspections are conducted to check for any defects in the electrode’s shape, size, or structure.

- Electrical testing: Electrodes are assessed for their electrical conductivity and impedance to ensure they can accurately and consistently relay electrical signals.

- Biocompatibility testing: Medical electrodes must undergo rigorous testing to demonstrate their biocompatibility, non-toxicity, and non-irritating properties.

By following these steps in manufacturing, medical electrodes are produced with the necessary precision, reliability, and biocompatibility for various applications in clinical diagnostics, monitoring, and treatment.

Use Cases of Medical Electrodes

Medical electrodes are used for various medical applications involving the conversion of ionic current energy in the body into electrical current for diagnostic and therapeutic purposes. This section discusses the use cases of medical electrodes in cardiac monitoring, neurological monitoring, and muscle stimulation.

Cardiac Monitoring

Cardiac monitoring is an essential aspect of healthcare where medical electrodes play a crucial role. These electrodes are employed in various applications, including telemetry, resting, stress, Holter, and general monitoring. They help detect cardiac abnormalities, such as irregular heart rates, conduction defects, and arrhythmias.

Telemetry – Medical electrodes facilitate the wireless transmission of real-time cardiac information for remote monitoring and diagnostic purposes.

Resting ECG – During a resting electrocardiogram (ECG) test, electrodes are placed on the skin to monitor the heart’s electrical activity while the patient is at rest.

Stress Test – Electrodes are used during the stress test to measure the heart’s response to physical activity.

Holter Monitoring – A Holter monitor records the heart’s electrical activity over an extended period, typically 24 to 48 hours, using medical electrodes.

Neurological Monitoring

Neurological monitoring involves the use of medical electrodes to detect, record, and analyze electrical activities in the nervous system, assisting in the diagnosis of various neurological conditions. Some examples are:

- Electroencephalogram (EEG): Measures brain waves using adhesive electrodes placed on the scalp, aiding in the diagnosis of epilepsy, sleep disorders, and other neurological conditions.

- Evoked Potentials (EP): Evaluates the electrical activity from specific neural pathways, helping to identify demyelinating diseases, such as multiple sclerosis.

- Electromyography (EMG): Monitors muscle and nerve fiber activity by placing electrodes on or near the muscles, assisting in the diagnosis of neuromuscular disorders, including muscular dystrophy and peripheral neuropathy.

Muscle Stimulation

Medical electrodes are used for muscle stimulation in various therapeutic applications, such as rehabilitation and pain relief. They deliver electrical impulses to the targeted muscles, causing them to contract and relax. Examples include:

- Transcutaneous Electrical Nerve Stimulation (TENS): This non-invasive technique uses electrodes to deliver mild electrical pulses to the skin, stimulating nerve fibers and reducing pain.

- Electrical Muscle Stimulation (EMS): Also known as neuromuscular electrical stimulation (NMES), EMS involves placing electrodes on the skin over targeted muscles to stimulate their contraction, helping with muscle rehabilitation and strength improvement.

- Functional Electrical Stimulation (FES): FES utilizes medical electrodes to activate paralyzed or weakened muscles in patients with conditions like spinal cord injuries, multiple sclerosis, or strokes, enabling them to perform functional movements, such as walking or grasping objects.

In summary, medical electrodes play a vital role in various diagnostic and therapeutic applications for cardiac monitoring, neurological monitoring, and muscle stimulation, providing valuable information about the patient’s condition and helping in the respective treatments.

Advances in Medical Electrode Technology

In recent years, there have been significant advancements in the field of medical electrodes, enabling the development of various types of novel materials, structures, and applications. Some of the most notable advancements include the use of carbon nanotubes (CNT), polymer-based materials like polydimethylsiloxane (PDMS) and wearable, flexible electrodes.

CNT/PDMS composites have emerged as a promising material for electrodes due to their unique properties such as high flexibility and good electrical conductivity. However, there are some fundamental issues that need to be addressed before these materials can become widely used in commercialized medical electrodes, such as their lower solubility and dispersion in polymer resins and their poor interfacial grip with polymers.

Flexible and wearable electrodes are another noteworthy development in medical electrode technology. These novel electrodes can enhance patient comfort and enable continuous biopotential monitoring in various healthcare settings. By utilizing materials with excellent mechanical and electrical properties, these innovative electrodes can effectively detect biosignals and facilitate remote monitoring applications.

Moreover, smart and wireless electrode technology has opened up new frontiers in personalized healthcare. By integrating sensors into the electrode designs, medical professionals can gather data on vital signs and monitor patients’ responses to therapies or medications effectively. This data can then be transmitted wirelessly for comprehensive and real-time analysis by healthcare practitioners, enhancing the diagnosis and treatment of various conditions.

Conclusion

Medical electrodes play a crucial role in the field of healthcare and medicine. They are essential components in sensing, stimulating, and treating various medical conditions. The manufacturing process of these electrodes involves the use of a lead for conduction, a metal electrode, electrode-conducting paste or gel, and often a metal snap for securing the lead.

These electrodes have grown to become pivotal in the development of electroceutical devices, which offer an alternative or complementary solution to traditional drug treatments. By directly stimulating the nervous system, these devices have been able to improve the quality of life for individuals affected by chronic diseases and debilitating disorders.

The core technologies that enable this growth include sensor technology for detecting biosignals, interfacial signal processing, analysis technology, printer and display technology for outputting results, and circuit technology that ensures safety considerations are met. This ongoing research and development in electrode technology and biomedical applications, such as electrosurgery and electrical stimulation, will continue to advance healthcare and treatment options for patients.